Applications

Elements are used in a wide variety of furnace applications, from small laboratory furnaces to large industrial heating processes, in different atmospheres and temperature ranges.

CERAMIC FIRING | HEATING ELEMENT | MELTING | HOLDING | ASSAYING PRECIOUS METALS | INCINERATION AND REGENRATION |

Ferrites | Tools | Non-ferrous (aluminum, magnesium, copper) | Non-ferrous (Aluminum, magnesium, copper) | Gold | Burning Organic Wastes |

Spark Plugs | Gears | Glass | Silver | Carbon Regeneration of Removal of Organics | |

Space Shuttle Tiles | Dies | Float Glass (Tin Bath) | |||

Graphite Shapes | Shafts | ||||

Phosphorescent Powders | Fluidized Bed Designs |

SINTERING POWERED METALS | BRAZING | FORGING | ANNEALING | Laboratory Research |

Iron Parts | Copper | Billet Heating | Bright Annealing of Stainless Steel | Thermal Conductivity |

Alloy Parts | Alloy Steels | Hand Tools | Stress Relieving | Thermal Expansion |

Non-Ferrous Parts | Silver | Automotive & Aircraft Valves | Glass | Flammability Testing |

Basic Powders & Grains | Tungsten Carbide | Jet Engine Blades | Modulus of Rupture Testing | |

|

| Infrared Spectometry |

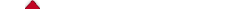

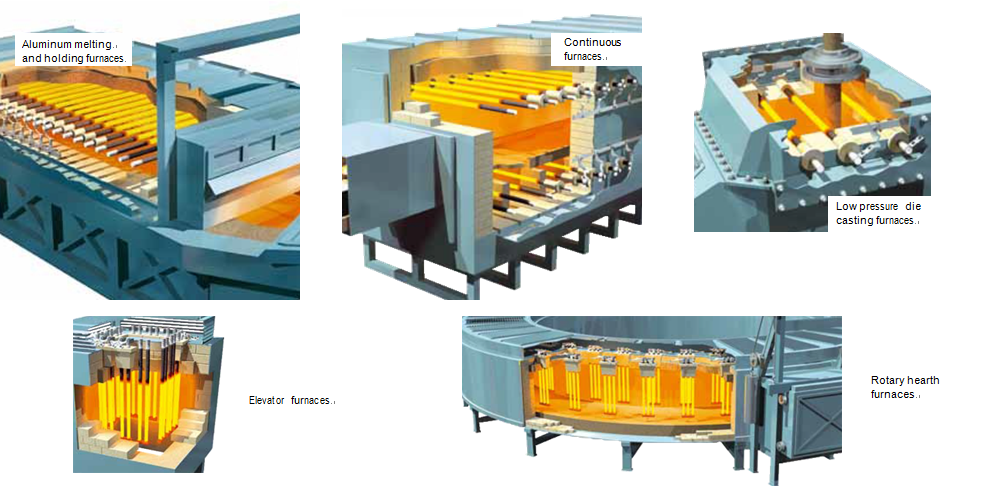

In many applications including: glass, ceramics, electronics and metal industries, and also for re- search and development. Examples of some typical furnaces where QS SIC elements are the natural choice are illustrated below:

Applications

The single ended connection of QS SG&SGR elements makes them ideally suited to various applications where standard elements cannot conveniently be used, such as where access would be difficult, or in any case where single ended connections are essential.

QS SG and SGR elements are used in a wide variety of furnace applications, from small laboratory furnaces to large industrial heating processes, in different atmospheres and temperature ranges. The elements allow great freedom in furnace design which, combined with simple installation and long operating life.

makes them the preferred choice in many applications including: Glass, ceramics, electronics and metal industries and also for research and development.

Examples of some typical furnaces where QS SG and SGR elements are the natural choice are illustrated below.

High temperature laboratory furnaces

•Creep testing, MOR and DTA

•General purpose box and tube furnaces

Batch and continuous furnaces to 1600°C (2910°F)

• Alumina ceramics

• Electronics components

• Tin oxide electrodes

• Luminous powders

• Powder metal sintering

Melting and holding of non ferrous metals

• Crucible or reverberatory

• Immersion heater

applications

QS SG and SGR elements are ideally suited to most types of high-temperature equip- ment, including:

• High-temperature laboratory furnaces

Creep testing, MOR and DTA

General purpose box and tube furnaces

• Melting and holding of non ferrous metals Crucible or reverberatory

Immersion heater

• Glass feeders

• Batch and continuous furnaces to 1600°C (2910°F) Alumina ceramics

Electronics components Tin oxide electrodes Luminous powders Powder metal sintering.

martin@qs-heatingelements.com

martin@qs-heatingelements.com